Rolled angle bending is a cost-effective process that eliminates sharp edges, improves strength, and delivers functional and cosmetic value. Tube-Tech Bending's new FACCIN angle roll system allows us to provide the latest in metal leg in and leg out angle bending capabilities at the best available price for a range of industrial-sized projects. This new piece of technology allows us the flexibility to meet our client's unique project needs by customizing any pipe or tube-bend to the ideal orientation and diameter. Our new FACCIN angle roll system also gives us the ability to provide rolled angle services for rings that can be bent helically, off-axis, or into compound tube bends.

Bending Angle Bending & Rolling Applications

Tube-Tec is an industry leader with decades of experience in leg-in and leg-out angle bending & angle rolling services for a wide range of industrial applications such as,

- Fan housings

- Tank supports

- Roof supports & roof systems

- Architectural accents

- Flanges

- Steering mechanisms

- Ladle lips

Click here to learn more about our process and about various pipe schedules.

Angle Bending Metal Types

Depending on your unique project requirements, angle bending may be performed on a variety of materials, including:

Tube Bending Sizes

Our team bends tubes in a range of sizes:

| ½" O.D. | 2⅓" O.D. |

| ¾" O.D. | 3" O.D. |

| 1" O.D. | 3½" O.D. |

| 1½" O.D | 4½" O.D. |

| 1¼" O.D. | 4" O.D. |

| 2" O.D. | 6⅝" O.D. |

| 2¼" O.D. | 8⅝" O.D. |

Request Tube-Tec Bending Angle Bending & Angle Rolling Services

From large-volume production orders to custom prototypes, Tube-Tec Bending accommodates any industry challenge. When your project requires responsive, experienced service, call our pipe bending facility at 713.264.0821. For your convenience, you can also contact us by submitting a secure online inquiry and a Tube-Tec Bending team member will be in touch promptly to discuss your angle bending specifications.

Competitive Advantages of Tube-Tec bending

Structural steel bending and rolling services for large-scale components, including wide flange beam bending, are among the most demanding metal modification tasks. Thanks to our 4-step metal bending process where we take clients through the consultation, design assistance, prototyping, and lastly manufacturing and delivery this is no project too hard to handle. This process allows us to meet even the most complex challenging requirements with efficiency, professionalism, and adaptability.

The Tube-Tec Bending Value Proposition

Tube-Tec Bending partners with dozens of markets to deliver expedited service and unparalleled customer support during your angle-bending project. We are proud to have earned a reputation for:

- Turnaround times that meet aggressive timelines without sacrificing quality

- Owner-operated service that sets your mind at ease

- Value-driven pricing to fit your project or facility budget

- In-house finish work that reduces transportation costs

- Proprietary technology & innovative solutions for any application requirement

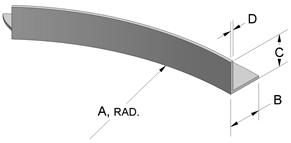

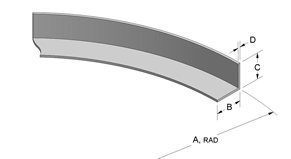

| Angles | |

|

Leg out |

|

Leg in |