If your industrial project requires the sourcing and procurement of specially modified metal and steel beams, the experts at Tube-Tec Bending provide cost-effective steel beam bending & rolling solutions on expedited timelines. Leveraging decades of experience that spans dozens of different industries, the Tube-Tec Bending team is headed by a dedicated, hands-on owner-operator and supported by state-of-the-art technologies based at our six-acre Houston facility. Our many years of experience have made us experts in the beam bending process.

Beam Rolling Capabilities

Our beam rolling capabilities cover metal and steel beams with widths of up to 20 inches and the full spectrum of beam types:

- I-Beams or as they are sometimes known, Junior Beams or S-Beams are mostly made from structural steel and are often used in the industrial construction sector. These structural I-Beams have various applications within the construction industry but their most popular are building a framework or other general structural support purposes.

- Wide Flange Beams - Have two parallel end units that are connected by a central web unit called flanges. W-Beams are commonly used as structural support in the industrial construction sector for buildings but are also the prime choice for bridges, highways, and overpass structures.

- S-Beams, Standard Beams - Are a type of I -Beam with much narrower flanges that are tapered and slope away from the inside. This design allows for the S-Beam to offer superior strength over beams that may have a wider flange. Made from structural steel, S-Beams can be applied to various industries such as residential and commercial building construction and shipbuilding.

- H-Beams - Like the name implies are shaped like the capital letter H and are designed with a thicker center web to take on more force during application. H-Beams tend to have a longer span which can often reach up to 300 feet making an ideal choice for larger scaled construction projects.

At Tube-Tec Bending, we use an innovative combination of techniques and technologies to modify steel beams to tight specifications with minimal waste and scrap metal byproducts. Thanks to our deployment of thorough documentation techniques, we generate customer-specific modification strategies quickly and efficiently and deliver reliable and predictable results time after time. For additional sizing information, click here to learn more about nominal pipe size & pipe schedules.

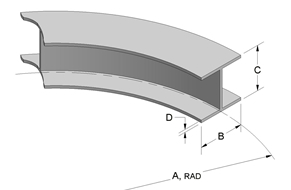

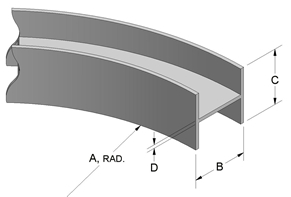

There are two primary methods used in beam bending applications, informally known as the "easy way" and the "hard way." Our staff excels at both, and our processes are supported by industry-leading equipment that ensures even the most demanding beam forming projects are completed on time and to industry-required guidelines.

| Beams | |

|

Easy Way |

|

Hard Way |

Competitive Advantages of Tube-Tec bending

Structural steel bending and rolling services for large-scale components, including wide flange beam bending, are among the most demanding metal modification tasks. Thanks to our 4-step metal bending process where we take clients through the consultation, design assistance, prototyping, and lastly manufacturing and delivery this is no project too hard to handle. This process allows us to meet even the most complex challenging requirements with efficiency, professionalism, and adaptability.

Our goal is to provide customers with responsive service characterized by courtesy, careful communication, and efficiency to fulfill their beam bending needs. We understand that timeliness is critical to our industry partners, so every phase of your production process is guided by promptness and professionalism. Because of our experience and state-of-the-art equipment, we are able to meet even the most demanding turnaround times while respecting your budget.

In addition, the Tube-Tec Bending team offers the versatility and experience with metal bending and rolling to generate ideal results. Our company has a long, proven history of innovation, and all work is performed and finished in-house to ensure it meets our demanding quality control standards and your industry guideline specifics.

Contact Tube-Tec Bending About Beam Bending

To request a beam bending estimate, or to discuss your project in detail with an experienced member of our production team, please call 713.264.0821 or use our secure online inquiry form. A Tube-Tec Bending professional will be in touch promptly!