At Tube-Tec Bending, we specialize in the manipulation of tubes and hollow structural sections of virtually any shape or size. While tube bending poses a number of specific challenges, our highly skilled and extensively trained technicians continually deliver outstanding work characterized by tight tolerances and conformity to customer specifications. Take a look at our complete processes page here, from initial order to prototyping, through delivery.

Tube-bending results are uniform, predictable and error-free, even when your project demands relatively difficult bending processes for square or rectangular tubing, or modification of the x-x axis. Working with structural steel, stainless steel, copper, titanium, aluminum, and exotics, we offer some of the best cold-rolling and bending and CNC tube bending capabilities in the industry.

Tube Bending Sizes

Our team bends tubes in a range of sizes:

| ½" O.D. | 2⅓" O.D. |

| ¾" O.D. | 3" O.D. |

| 1" O.D. | 3½" O.D. |

| 1½" O.D | 4½" O.D. |

| 1¼" O.D. | 4" O.D. |

| 2" O.D. | 6⅝" O.D. |

| 2¼" O.D. | 8⅝" O.D. |

| Tubing | |

|

Square |

| Rectangle | |

|

Pipe/Round Tube |

Tube-Tec Bending: Our Team

The Tube-Tec Bending team is led by our hands-on owner-operator, who works closely with customers at every stage of the project life cycle and personally supervises all in-process work. Committed to client-focused service at every project stage, we provide very fast turnaround rates, even in cases where customer demands necessitate greatly expedited timelines.

Collectively, our team offers decades of intensive industry experience, helping us meet even the most complex challenges with ease and confidence. We also have a proven track record of innovation, and the Tube-Tec Bending team has initiated numerous proprietary techniques and technologies that no other metal modification shop can offer.

Competitive Advantages of Tube-Tec bending

Structural steel bending and rolling services for large-scale components, including wide flange beam bending, are among the most demanding metal modification tasks. Thanks to our 4-step metal bending process where we take clients through the consultation, design assistance, prototyping, and lastly manufacturing and delivery this is no project too hard to handle. This process allows us to meet even the most complex challenging requirements with efficiency, professionalism, and adaptability.

Our Houston Tube Bending Facility

Our Houston, Texas-based company is housed at a six-acre, crane-served facility. Outfitted with state-of-the-art technologies, we are capable of processing tube bending requests from small-batch prototypes to large-volume orders. The Tube-Tec Bending production facility also includes a new FACCIN angle roll, which enables us to deploy the very latest best practices at highly advantageous price points. We also provide CNC tube bending services when the application is right.

Get a Free Tube Bending Estimate

If you would like to obtain a fast, free, accurate project estimate, or to discuss your particular needs in more detail, please contact Tube-Tec Bending by phone or online. Knowledgeable customer service representatives are available to process your request immediately, and it is our pleasure to provide you with superior service.

Square Tube Bending

The modification and manipulation of square tubes and hollow structural sections demands advanced considerations.

Learn More

Rectangle Tube Bending

At Tube-Tec Bending, we take great pride in being equal to even the most difficult tube bending tasks.

Learn More

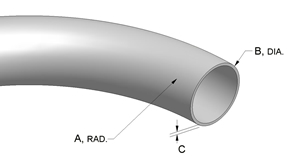

Round Tube Bending

We provide cost-effective round tube bending services that lead to error-free finished products with tight radii and strict conformance to customer specifications.

Learn More